New Look, Same Commitment to Excellence

We've refreshed our brand to better reflect our innovative approach to automation.

Precision Automation

for Modern Industry

We design, build, and integrate advanced robotic systems, PLC automation, and AI-powered vision solutions that transform manufacturing operations.

Advanced Manufacturing Solutions

From robotic arms to AI-powered vision systems, we deliver end-to-end automation solutions engineered for precision and reliability.

Advanced Robotic Applications

In collaboration with Fanuc America and Universal Robots, we deliver robotic solutions tailored for automotive, pharmaceutical, food & beverage, and logistics industries.

Sorter Conveyors & Material Handling

Innovative sorter conveyor systems for food processing, packaging, logistics, and manufacturing with high standards of quality and reliability.

Warehouse Automation

Autonomous Mobile Robots (AMRs) that seamlessly integrate into existing workflows for intelligent material transport and real-time fleet coordination.

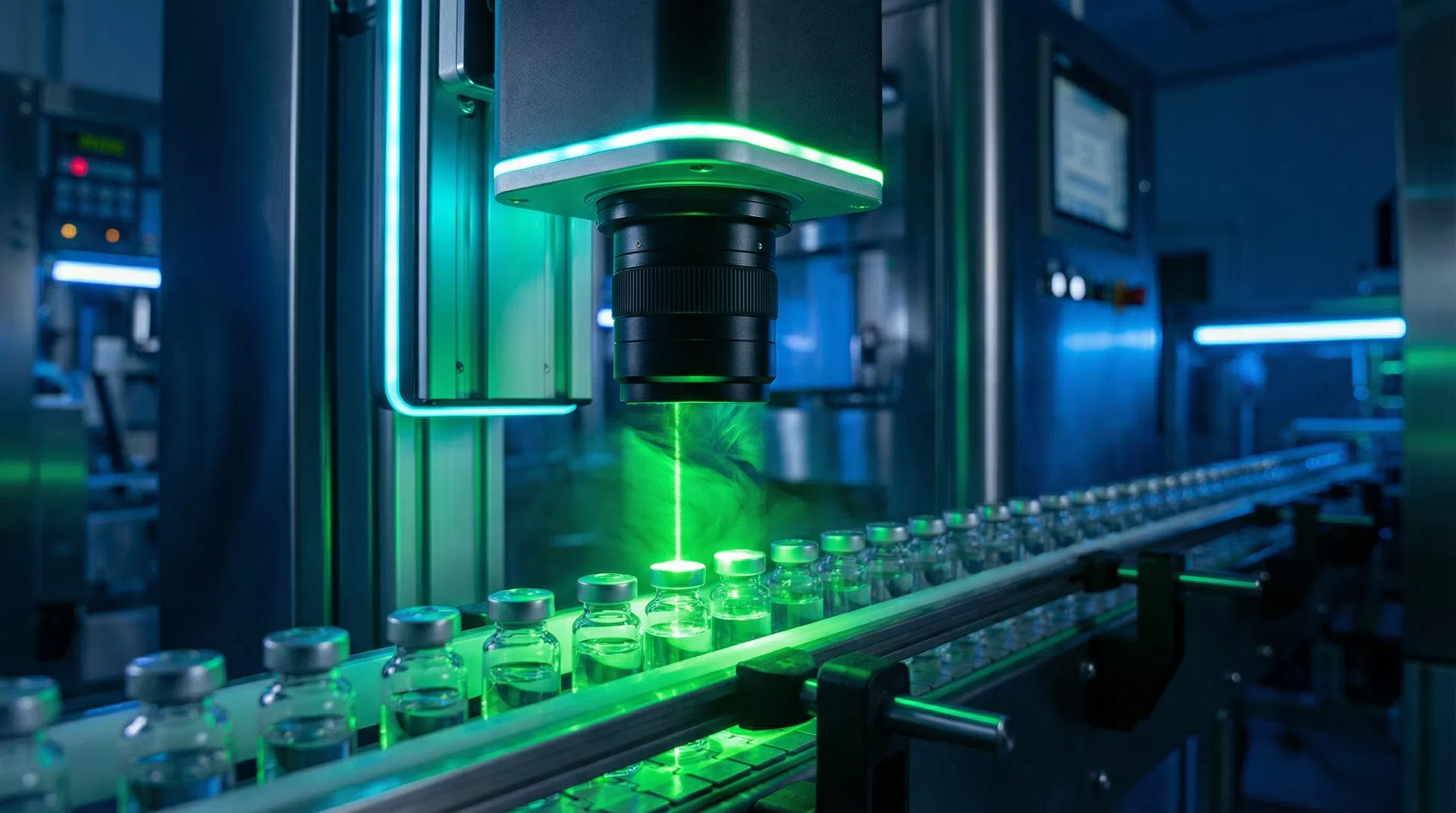

Machine Vision AI

In partnership with Zebra Technologies, we deliver cutting-edge machine vision solutions for defect detection, quality assurance, and process optimization.

PLC Panel Building & Programming

Custom PLC solutions with seamless integration, real-time monitoring, fault detection, and scalability for cost-effective automation.

Security Camera Systems

Integrated security systems with optimized camera placement, PoE/IP infrastructure, real-time monitoring, and scalable VMS platforms.

Structured Cabling

Organized cabling systems with proper labeling, EMI-aware routing, and industry standards compliance for dependable performance.

Trusted Across Industries

Our automation expertise spans diverse sectors, delivering tailored solutions that meet each industry's unique requirements.

Automotive

Complete automated systems for assembly lines, welding, and quality inspection.

Pharmaceutical

Vision inspection and packaging automation for regulatory compliance.

Food & Beverage

Hygienic automation solutions for processing, packaging, and sorting.

Logistics

Conveyor systems, AMRs, and sorting solutions for distribution centers.

Manufacturing

End-to-end production line automation with PLC integration.

Education

Security and infrastructure solutions for educational facilities.

Case Studies

Real-world automation solutions delivering measurable impact for our clients.

FANUC Robotic Palletizing System

The Challenge

- Worker injuries from repetitive manual palletizing

- Chronic labor shortages across all shifts

- GMP deviations and contamination risk

- Throughput variability between shifts

- Product damage during manual handling

- Floor space constraints in production area

- Training & validation burden for new operators

Our Solution

Vector Automation successfully implemented a FANUC robotic palletizing system that enables fully autonomous line operation — running three shifts, 24/7 — without operator intervention. The solution delivers consistent throughput, eliminates manual palletizing labor, improves safety and GMP compliance, and ensures reliable, around-the-clock production performance.

Key Results

Interested in a similar solution?

Let our experts design a custom automation system for your facility.

Sorter Conveyor with Tunnel Inspection System

The Challenge

- Manually sorting boxes with many operators causing quality problems on the final product

- Manual barcode reading causing operator fatigue and errors

- Inconsistencies between warehouse database and actual inventory

- Inventory discrepancies leading to fulfillment delays

- Slow throughput from manual operations causing bottlenecks

- High labor costs for dedicated scanning operators

- Inability to maintain 24/7 operations without staffing challenges

Our Solution

Vector Automation successfully implemented a fully automated sorter conveyor with a Cognex inspection tunnel to read 100% of boxes coming on the line and sorting every box to the right diverter to automatically sort every product to the right position. Additionally, all information was sent to the customer database to update inventory in real-time — running three shifts, 24/7 — without operator intervention. The solution delivers consistent reading, eliminates manual scanning, improves accuracy and compliance, and ensures reliable, around-the-clock production performance.

Key Results

Interested in a similar solution?

Let our experts design a custom automation system for your facility.

Full Stack Automated Serialization System

The Challenge

- DSCSA compliance required for manufacturing and exporting pharmaceutical products to international markets

- End-to-end serialization, aggregation, and traceability needed across entire packaging operation

- Stringent pharmaceutical regulatory standards demanding full-stack serialization solution

- Seamless integration required with existing packaging line equipment

- Continuous 24/7 operation with minimal downtime

- Integrity and accuracy of serial number data across all packaging levels

Our Solution

Vector Automation, in partnership with Systech International, implemented a full-stack Systech serialization system on the customer's packaging line. The solution included complete integration and orchestration of all line-level and enterprise components — PLCs and line control systems, printers for serialized labeling, vision systems and cameras for code verification, barcode scanners for aggregation and validation, and centralized serialization and data management software. Vector Automation engineered a tightly integrated system ensuring real-time communication between devices, robust error handling, and compliance with pharmaceutical regulatory requirements.

Key Results

Interested in a similar solution?

Let our experts design a custom automation system for your facility.

Engineering Excellence, Delivered

At Vector Automation, we understand the diverse challenges businesses face in optimizing operations. Our team of certified Project Management Professionals harnesses advanced AI technologies and strategic expertise to drive lasting results.

From initial consultation to seamless implementation, we collaborate with you to craft customized solutions that precisely align with your unique requirements. Every project is backed by proven methodologies and industry-leading partnerships.

Technology Partners

Assessment

We analyze your current operations, identify inefficiencies, and map out opportunities for automation improvement.

Design & Engineering

Our engineers design a tailored solution using proven PM methodologies, ensuring every component meets your specifications.

Implementation

Seamless integration with your existing systems, including programming, testing, and commissioning on-site.

Ongoing Support

Continuous monitoring, maintenance, and optimization to ensure long-term operational success and maximum ROI.

Ready to Transform Your Operations?

Schedule a free consultation with our automation experts. We'll analyze your needs and recommend the right solution.

Our Experts Will:

Phone

(616) 279-6046Location

250 Monroe NW Suite 400, Grand Rapids, MI, 49503, USA